Menu

close

Table of Contents

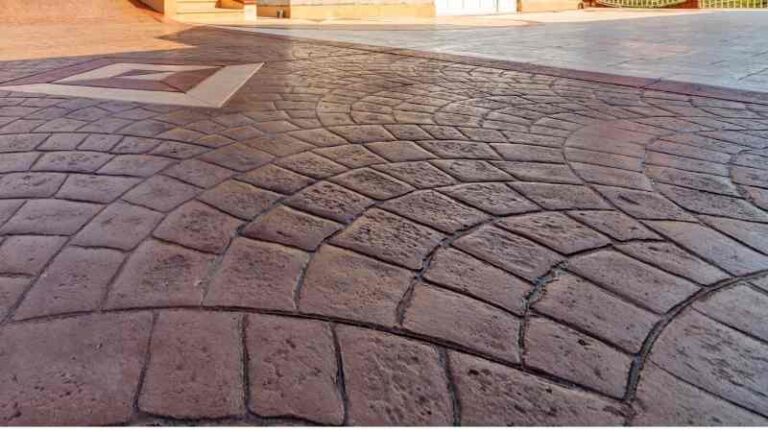

Stamped concrete is a versatile and endlessly customisable way of improving the look of any outdoor area. And it can even be used inside, for example, for countertops. After it has been laid and set in place, concrete is very low maintenance and durable, but it has to be laid correctly. And a big part of getting concrete right is sealing it and sealing it at the right time.

Most companies will suggest leaving a full 28 days before sealing stamped concrete. This might seem like a long time to wait with unsealed concrete but it is for some very good reasons.

Stamped concrete is a relatively modern way of creating a surface for a variety of settings. You can see it in a stamped concrete patio, a stamped concrete driveway, stamped concrete floors, stamped concrete countertops, and even a stamped concrete pool deck.

Stamped concrete is a decorative concrete option, and this decoration is created by applying a pattern mat to wet concrete to leave an imprint. The imprint can mimic a wide variety of surfacing, including stonework, cobblestones, slate, and more.

One of the main benefits of using stamped concrete is that it allows you to get the look of a very expensive surface option at a fraction of the cost. The materials themselves can be much cheaper, especially when compared with something like slate, and it is much quicker to install so the labour costs can also be much cheaper.

Not only can you choose whatever pattern you want to give the concrete surface the texture that you are looking for, but stamped concrete can also be coloured whichever way you want as well.

Concrete is a mix of different ingredients which together create a tough, durable, and easily applied building material. It is the second most used substance in the world after water and its uses are incredibly varied.

The main ingredients of concrete are Portland cement, water, and an aggregate (usually sand or gravel). Sometimes other ingredients are added to slightly change the properties of the concrete but these ingredients are the ones you will find in every concrete mix.

Before mixing the concrete, you will have created a sub-base. This is an area dug out of the ground with gravel placed inside to create a base for your concrete. The depth can vary depending on how strong you need the concrete to be. Once the concrete is mixed, it is poured into the sub-base.

Creating stamped concrete surfaces needs to happen very soon after the concrete has been poured, and while it is still wet. You can only create a pattern on new concrete and not existing concrete because if the concrete has dried, you won't be able to make an impression with the pattern mat.

The patterned mats are carefully laid onto the concrete (it is often better to work out the configuration before the concrete is poured) taking careful account of crack control joints and ensuring that the pattern lines up perfectly.

Once the concrete has been poured and stamped, the curing process begins. This is one of the most important steps because it sets the concrete up for its longevity by ensuring that it has the strength it needs.

When the concrete is mixed, water is needed to create the reaction that allows the cement to bond to the aggregate and this water needs to evaporate for the concrete to fully bond. The generally accepted length of time for concrete to fully cure is 28 days, but this can vary depending on weather conditions. The curing time can be much shorter if the air temperature is warm and it is dry but if there is moisture in the air and it is cold, then it won't cure faster. It generally doesn't take any longer than 28 days, as long as water doesn't directly get onto the concrete, for example, if it isn't covered with plastic sheeting and it starts to rain.

The concrete sealer can only be added after the curing process has been completed. This is one of the most important steps in the entire process because applying the concrete sealer to your stamped concrete too soon can compromise the integrity of the concrete.

Remember that the curing process is all about allowing all of the excess moisture in the stamped concrete to evaporate. If the stamped concrete sealer is applied before the curing process has finished, it will seal in any moisture that remains in the concrete and it will have no way to escape. This means that the cement and aggregate in the concrete will never fully bond and the concrete will be weaker and more prone to cracks and damage.

Sealing a surface that has moisture can also prevent the sealer from properly adhering to it. This can result in delamination, which is wear the sealer layer lifts from the concrete, or it can lead to blooming, which is patches of concrete where the sealer hasn't stuck. Both of these can lead to unwanted staining as well as a higher chance of damage to the concrete over time.

Concrete sealers aren't just added to decorative concrete. There are applied to any concrete surface. If you have exterior stamped concrete then it can be especially important to apply a sealer, but it is also needed for a stamped concrete surface that will remain indoors.

An unsealed stamped concrete surface, or any concrete surface, is porous. What this means is that water can easily soak through the surface of the concrete and penetrate the concrete slab. So if you have used a pressure washer on a concrete driveway, for example, the water won't evaporate off the surface. Instead, most of it will soak through.

This can be a major problem, especially in the climate we have in the UK, because the water in the concrete will go through the freeze-thaw process. When the air temperature drops, the water that is in the concrete will freeze and expand, and then when it thaws it will turn to liquid again. Over time, this expansion and movement within the concrete can lead to cracks.

When you seal stamped concrete, you are creating a waterproof layer that stops the concrete from being porous and prevents any water from penetrating the top layer. This helps to protect the concrete from the damage caused by the freeze-thaw process and gives it a better chance of lasting for longer.

Sealing stamped concrete will also protect from damage caused by abrasions. In places like concrete driveways, in particular, where there is likely to be heavy traffic, there is always a chance of the concrete surfaces getting damaged. The layer of protection from a sealer can help to reduce the chances of this happening.

One of the biggest problems that people have with stamped concrete, and especially in something like a stamped concrete patio or pool deck, is that it can be very slippery. Applying a sealer that has slip resistant additives can stop your stamped patio or pool decks from being dangerous when they get wet.

Getting the right sealer type can make all the difference, both to how well your decorative concrete lasts, and to how it looks. With stamped surfaces you are going to be looking for a very particular look. So if you apply sealer that is high gloss, for example, when the look you are trying to achieve would have a matte finish, your stamped surface won't look right.

There are wide variety of sealers available. Some sealers, known as penetrating sealers, are designed to penetrate into the concrete where there is a chemical reaction between the sealer and the concrete. They work by increasing the surface tension of the concrete to create beading when there moisture hits the surface. This prevents the moisture from penetrating into the concrete slab.

Penetrating sealers are favoured by a lot of people because they are long lasting because of how closely they adhere to the concrete all the way through. They also provide a matte look with no gloss that doesn't alter the look of the concrete, which can make stamped surfaces that are designed to look like slate, stone, etc look more realistic.

There are a wide range of topical sealers available, such as acrylic sealers, which can give you different looks. Rather than penetrating into the concrete, they create a thin coat over the surface which prevents water from getting into the concrete. They tend to completely dry much more quickly than penetrating sealers.

They are also more flexible in terms of the finishes you can achieve. They can have various different gloss levels that can give you everything from a glossy sheen to a matte look, and you can even get tinted sealer that can help enchacne the surface colour of your concrete. Most sealers provide protection from UV rays but some will turn yellow in the sun. The best sealer for you will depend on exactly how you want your concrete surface to look.

Even if there is an existing sealer that has been applied, resealing stamped concrete surfaces on a semi-regular basis is always a good idea. The guidance is usually to aim to apply sealer to the surface every one to five years so that you can retain the protection ghtat the original sealer provided.

Resealing stamped concrete driveways is a job that you can do yourself but it can help to have a professional come in to help you. This is because it is important to perfectly apply the right sealer evenly across the entire surface.

It is usually better to use two coats rather than one, letting the first coat air dry before applying the second coat (this usually takes around 24 hours although you can use a leaf blower to speed the process along). And remember that it is just as important to apply the second coat evenly as it was the first one. Resealing stamped concrete will help the concrete to retain its colour and will help to protect it from weather exposure as well as abrasions and harmful chemicals.

It can be important to make sure that your old sealer and new sealer match in terms of their components as they may react differently together if they are mismatched.

Sealing the surface isn't the only maintenance that you need to do for an existing stamped surface. You will also need keep it clean. This will keep your stamped concrete looking at its best for longer and avoid letting any stains build up. Although your sealer will protect against most things that leave stains, if they are left on there for too long then the stains can eventually penetrate.

It is easy to clean stamped concrete. You can use a pressure washer or a garden hose with some liquid dish soap and that will normally be enough. If you do use a garden hose, it can be helpful to also get in there with a push broom to make sure that you get rid of any dirt and debris.

You should avoid using any deicing salts on your concrete driveway. The salt can cause erosion which will allow water to penetrate the concrete and begin the freeze-thaw process, and eventually cause damage.

Sealing stamped concrete is an essential step in the process of creating a concrete area that is durable and long-lasting and the sealer should only ever be applied after the concrete has completely dried (i.e. after the curing process has finished). Sealing the concrete while it is still wet will interfere with the curing and will leave the concrete open to damage.