Menu

close

It's surprising how many people don't realise that their driveway in Harrogate makes a statement about their home.

Your house can look like a palace, but if the driveway is overgrown with weeds or cracked and broken, then it adds an air of neglect, spoiling the effect that you are trying to achieve.

Is your driveway in need of an upgrade? If so, you need to know what your options are. This guide is designed to help you in this area, providing all the information you need to make the right decision.

There are several to choose from, each with its own benefits. Some are obviously cheaper than others, but every one of them offers a practical and achievable method of improving the kerb appeal of your property. This is good news, whether you intend to sell your home or simply want to improve the overall appearance.

Here are some of the more popular options:

Probably the most cost-effective solution, this is favoured by homeowners with a large to cover. It is simple to lay, fully permeable and easily maintained.

It's a good idea to also install block paving around the edges to contain the gravel. This provides a more finished look and adds a touch of style to the end result.

A firm favourite for many years, this is an excellent way of enhancing any home. The range of colours and styles is vast, allowing you to create a unique and appealing look to your new driveway.

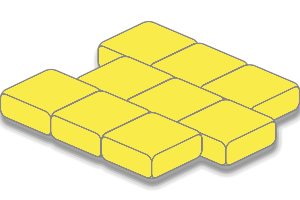

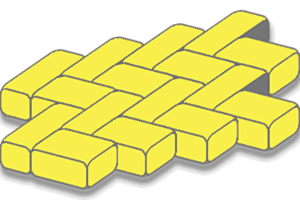

Blocks are available in two types: concrete and clay.

Clay paving blocks are sometimes referred to as bricks, but these are not the same as house bricks. These are much tougher, designed to withstand the constant weight of vehicles parked on top. House bricks would crumble after a while.

Concrete paving blocks are also very durable and come in a wide range of finishes and colours. You can choose from a traditional rustic look, similar to cobblestones, to a sleek contemporary style.

This is a fairly new addition, and it may not seem appealing to some as it evokes memories of decades gone by, where roughly laid concrete slabs with tough, abrasive surfaces were common. As hard-wearing as they were, they did nothing for the look of the property!

These days, you can have a good-quality concrete driveway laid that is coloured and printed to resemble block paving. It's relatively quick to instal and cures in a couple of days, making it a convenient and cost-effective choice.

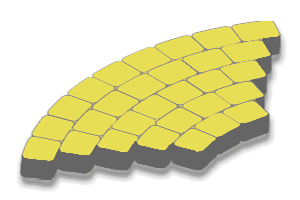

Now we come to what is widely regarded as the superior option out of all those listed here: resin-bound driveways.

Before we proceed, you should be aware that there is a similar type known as resin bonded driveways.

The difference between the two is that with resin-bound driveways the aggregates (gravel and crushed stones) are mixed with the resin before it is trowelled into place. With resin bonded surfaces the resin is applied first and the stones are scattered across the top, resulting in a very rough texture. Also, each method uses a different type of resin.

We're keeping the focus on the system known as resin-bound driveways, as they offer better all-round durability and value for money, as well as providing a fantastic finish.

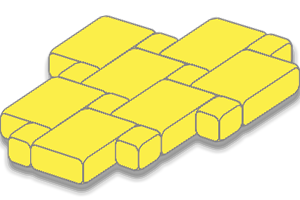

In addition to loose gravel set in resin, you can also get resin-bound paving. This is basically block paving with a coating of resin to seal it. This has the advantage of being easier to clean and there is no risk of stones becoming loose. It is also highly resistant to staining and simply needs to be swept occasionally to keep it free from debris.

Let's find out!

Traditionally, driveways were made of gravel, concrete, tarmac, or asphalt. While these served a purpose (and still do, in many cases) they are not to everyone's taste and they don't always provide the best results. They can also begin to look drab and discoloured or become cracked and damaged as they are worn out by time and weather. Gravel gets scattered, and bare patches appear, often allowing puddles to form and weeds to sprout. Tarmac sinks, making an uneven surface that looks unsightly and could be bad for your car.

Are resin-bound driveways any better?

Absolutely.

To begin with, some traditional driveway surfaces (such as tarmac or older concrete driveways) are not porous or permeable. This can be a problem as rainwater simply runs off into the local drains. When you have several thousand homes with driveways like this, the surface water overwhelms the drainage systems to cause localised flooding. And because most of these have cars parked on them, any oil or other pollutants are washed down into the drains too.

Good-quality resin-bound driveways are permeable. The stones are mixed with resin before installation and are designed to include microscopic fissures that allow water to soak through. This acts as a filter, drawing out pollutants and letting the rainwater soak away from the driveway surface naturally.

This is great news, as it is SUDS compliant. The SUDS (Sustainable Urban Drainage System) scheme was implemented to manage stormwater in towns and cities that causes flooding, costing billions of pounds of damage and lost livelihoods, not to mention putting lives at risk.

A resin-bound driveway doesn't require planning permission in Harrogate. The regulations state that any new driveway that is under 5 square metres or which has a permeable surface does not need prior planning permission. This cuts out a potential headache immediately, allowing you to proceed without the hindrance of red tape and bureaucracy.

Resin-bound surfaces don't usually allow weeds to erupt, as you may see with tarmac and concrete. The odd one may pop up (from seeds dropped by birds) but these can be easily be pulled out. The resin is flexible and crack resistant, lasting for many years with little maintenance required. Hosing your resin driveway with cold water and sweeping it with a stiff bristle brush should be enough to keep it looking great. There is a risk of staining if debris is left on the surface for a long time. If it does become stained, these can be gently cleaned off using a pressure washer (at a maximum of 150 bar) with a fan-type lance.

A professional driveway company should offer a 21-year guarantee on your resin drive. This gives you some idea of how long these driveways might last! With careful use, your resin-bound driveway should last for many years. You can help by avoiding things like chemical spills and damage. It is best not to undertake vehicle maintenance on a resin bound surface. However, if you have no alternative, take precautions to stop things such as brake fluid and fuel leaking onto the resin, as this is corrosive.

Motorbike stands and car jacks can damage the surface as they concentrate pressure on one point. If you need to raise your car, stand the jack on a flat piece of wood to protect the surface. You should also take care when dragging items over the surface, such as a heavy plant pot, as this can cause scratches.

For the very best results, UV stable polyurethane resin is used, and never epoxy resin. UV stable means that the colour within the resin-bound surfacing is protected from sunlight, otherwise, the colour would fade over time.

Although non-UV resin is available, and is a cheaper option, it is always best to use UV stable resin to ensure that your driveway looks its best for longer.

In some cases, a resin-bound driveway can be laid directly on top of an existing surface, provided that it is in good condition.

The best surfaces are:

Resin-bound gravel can be laid onto an existing tarmac surface if it is in a suitable condition and has an appropriate sub-base (MOT-3, for example*). It also needs to be the right depth in order to support the weight for its expected use.

Before using any existing concrete surface, it must be thoroughly cleaned and a polymer primer applied. Without primer, the resin-bound overlay will fail to adhere to the concrete. In this case, the only option is to remove the materials and start the project from scratch.

If a new concrete base has been laid (ideally on a sub-base of MOT-1), you will need to allow adequate time for it to cure before having your resin-bound driveway installed. This should be at least seven days but can take up to a month.

*the sub-base is a compacted layer of crushed aggregates on the subgrade (the ground surface) that helps to distribute the load over a wider area, as well as aiding drainage. MOT-3, in this case, refers to the grade of the crushed aggregate, which is permeable and therefore SUDS compliant. Although the grading system is still widely referred to as MOT (as in the old Ministry of Transport), the proper term is now DTp 3.

First, the surface will be checked to see it if is suitable and stable. Any cracks or damage will be repaired. Ideally, the sub-base will be porous tarmac or concrete.

Before the materials are mixed, the area must be completely clean and dry. Resin-bound installation should never take place in the rain or if it is forecast within 4 hours of completion.

The surface will be primed and checked once again to make sure it is dry.

The resin-bound surface is then mixed and troweled into place, after which you should allow at least 8 hours for it to cure. However, it is advisable to avoid walking on the surface for around 24 hours. If the temperature is below 15º then the contractor may use an accelerator to speed up the curing process.

Some people are concerned that a resin surface may be slippery, but this is not true. In any case, crushed glass is often added to the resin-bound stone before it has cured to ensure that the driveway surface has anti-slip properties.

It all sounds pretty simple, but the mixing process alone is complex, requiring specialist knowledge to get it right. You will also notice that the installation team will bring a vast array of equipment, each piece of which is vital to the success of the project.

Many of these items will have to be brand new or at least spotlessly clean before use, as the installation process can become a sticky and messy job very quickly. The last thing you want is your beautiful resin driveway stained and blighted by a dirty trowel or shovel.

This highlights just one of the differences between a trustworthy, reputable resin driveway specialist and a company that will do the job 'on the cheap' but will lack knowledge and professionalism.

They are almost literally endless!

Resin-bound gravel uses a vast range of coloured aggregates that provides a stunning variety of colours and finishes. The beauty of this is that the colour range is achieved by using natural aggregates, recycled materials, and marble. The aggregate size also allows for a variety of textures.

Whatever your choice of colour, there's bound to be one to match the style and tone of your Harrogate property. Do you live in a traditional, brick-built home in the suburbs? Then there's an amazing range of warm golds and yellows that will compliment your house perfectly.

Do you have a sleek, contemporary house with clean lines and a crisp finish? Then perhaps a slate, gunmetal grey, or silver coloured resin driveway would show it off to great effect.

Maybe you want to be a little more daring, with a fresh pink colour? Or you might be more reserved, opting for a classic beige or cream that offers a calm, classy feel.

Want to make a bold statement with your Harrogate home? Then what about a pure black or monochrome finish to your resin driveway?

The best part is, all of these can be made in different shades and textures and can be made into geometric patterns, house numbers, monograms, favourite sports logos - whatever you can conjure up in your imagination, your resin-bound driveway installation can be designed to suit it!

Resin driveway costs will always depend on the size of the project (for example, a double driveway would obviously be more) and the labour costs charged by local contractors, as well as the type of materials and designs you have chosen.

As a very general guide, you might expect resin-bound paving to cost approximately £60 per square metre. This will vary according to where you are located in the UK.

But when you consider that a good-quality resin-bound drive that is laid by a licenced, professional installation team is going to look fantastic, add value to your home, and last for at least a couple of decades, this is clearly a sound investment.

To end with a cautionary note - resin-bound driveways are a relatively new arrival in the UK, and as such, there is no governing body to regulate the installation. Sadly, this means that anyone can claim to have the knowledge and experience to install your driveway, but this may not be exactly true.

It is absolutely essential that you choose a professional and reputable installation company for your resin-bound driveway. There are many companies who will offer to do this at a cheaper rate but will provide second-rate workmanship that will cost you much more to put right. In all probability, the finish will be poor and the materials will not stand the test of time.

It is in your best interests to seek independent reviews and testimonials, check local safe trade listings, and get some word-of-mouth recommendations before making your choice.

Only a licensed, professional driveway installations team can provide the high-quality finish that you have paid for and that you deserve.

So, for instant kerb appeal, you have a range of options open to you when it comes to upgrading your driveway. You could choose loose gravel, which is probably the cheapest solution. You may go for block paving or imprinted concrete, both of which offer excellent results and a beautiful clean finish.

But for a stunning look that's certain to impress, you can't beat resin driveways. They are low maintenance, they provide a permeable surface that allows natural drainage, and they don't require planning permission. And you don't have to be limited to just your driveway: resin-bound surfaces can be used to create charming patios and footpaths too!

Whether for commercial or residential driveways, resin-bound surfacing offers an attractive and cost-effective solution.